The Haffner SC 220/80 is a Profile Machining Center designed to perform all cutting, milling, drilling, and marking operations on aluminum profiles within a single, computer-controlled machine.

Haffner Machinery

Key Features:

Integrated Operations: Combines cutting, notching, milling, drilling, and marking processes, streamlining production and ensuring consistent quality.

Automatic Profile Handling: Equipped with a servo-controlled gripper that positions profiles horizontally and vertically, accommodating various designs and sizes.

Precision Cutting: Utilizes a 600 mm diameter saw blade capable of automatic cutting at angles between 45° and 135° with 0.1° increments, controlled by servo motors for high-speed and precise operations.

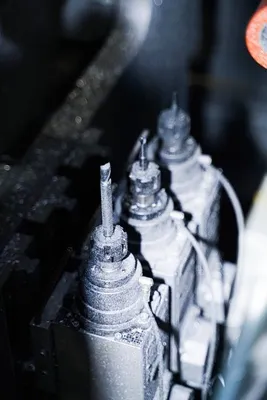

Advanced Milling Capabilities: Features a milling group with 12 tools, allowing for complex operations such as angled water drainage channel openings, drilling, and milling with high accuracy.

User-Friendly Interface: Operated via a 15-inch touch screen connected to a high-performance industrial PC running Windows 10, facilitating easy integration with various window production software and remote service capabilities.

Efficient Waste Management: Includes an automatic conveyor system to transport waste parts to a designated chamber, maintaining a clean working environment.

Technical Specifications:

Power Supply: 400V, 3-phase, 50/60 Hz

Total Power Output: 20 kW

Maximum Profile Processing Dimensions:

Height: 160 mm (6.29 inches)

Width: 130 mm (5.11 inches)

Profile Lengths:

Minimum Raw Profile Length: 1,000 mm (39.37 inches)

Maximum Raw Profile Length: 6,500 mm (255.90 inches)

Minimum Processed Profile Length: 350 mm (13.77 inches)

Machine Dimensions:

Height: 2,500 mm (98.42 inches)

Length: 15,300 mm (602.36 inches)

Width: 3,600 mm (141.73 inches)

Machine Weight: 5,700 kg (12,540 lbs)

We use cookies to improve your experience. Privacy Policy.